How can we help you?

)

craftworks GmbH

Schottenfeldgasse 20/6a

1070 Vienna

navio optimizes manufacturing processes with MLOps, enhancing efficiency and product quality.

:quality(80))

Know-How

reading time: 8 min

Bianca Peiu

:quality(80))

Manufacturers face an increasing demand to enhance efficiency, improve product quality, and maintain flexibility within rapidly changing production environments. Machine Learning is one important tool for meeting these demands. In consequence, the management of Machine Learning models (MLOps) is becoming an essential capability.

MLOps is a set of practices that standardizes and enables the deployment, monitoring, and management of artificial intelligence models, ensuring seamless integration with production systems. However, establishing MLOps within an organization from scratch is a significant challenge. This is where MLOps tools come into play.

navio is an advanced MLOps tool leading this transformation. It integrates deep learning models and computer vision into manufacturing processes, focusing on efficiency, precision, and real-time monitoring. By leveraging deep neural networks and support vector machines, navio enables manufacturers to tackle complex tasks like defect detection, quality control, and predictive maintenance.

navio empowers manufacturing teams, including MLOps engineers, data scientists, but also non-technical staff to deploy and manage machine learning models that integrate smoothly with production systems. With this powerful platform, manufacturers can use their own data to optimize operations, lower costs, and improve product quality.

MLOps, or Machine Learning Operations, brings together the development and management of machine learning systems. Without the right tools and processes, it can be difficult to deploy and maintain machine learning models effectively.

From the early days of machine learning, one of the biggest challenges in adoption was the lack of expertise in bringing models into production. While many were creating models in notebooks, few knew how to scale them or integrate them into live systems. Additionally, processing the underlying data and maintaining consistency across environments added further complexity.

This is where MLOps tools like navio play a crucial role. MLOps standardizes and simplifies the development and deployment of ML models, ensuring that they are not just built, but actually can be used to provide valuable insights and inputs for real-world use cases. These tools help bridge the gap between model development and real-world deployment, enabling continuous monitoring, feedback, and improvements.

As manufacturing operations become more complex, the need for real-time insights and data-driven decisions has grown. This has led many companies to invest in MLOps, recognizing its role in optimizing the machine learning lifecycle. 47% of manufacturers are already using AI to improve product quality and boost operational efficiency. Additionally, 30% of those not currently using AI plan to adopt it within the next five years, according to a McKinsey & Company report.

navio is an end-to-end MLOps platform that optimizes ML operations for manufacturers. It helps them manage, deploy, and monitor machine learning models on a large scale. Unlike other solutions, navio integrates seamlessly with existing manufacturing systems, ensuring that AI/ML models perform efficiently in complex industrial environments.

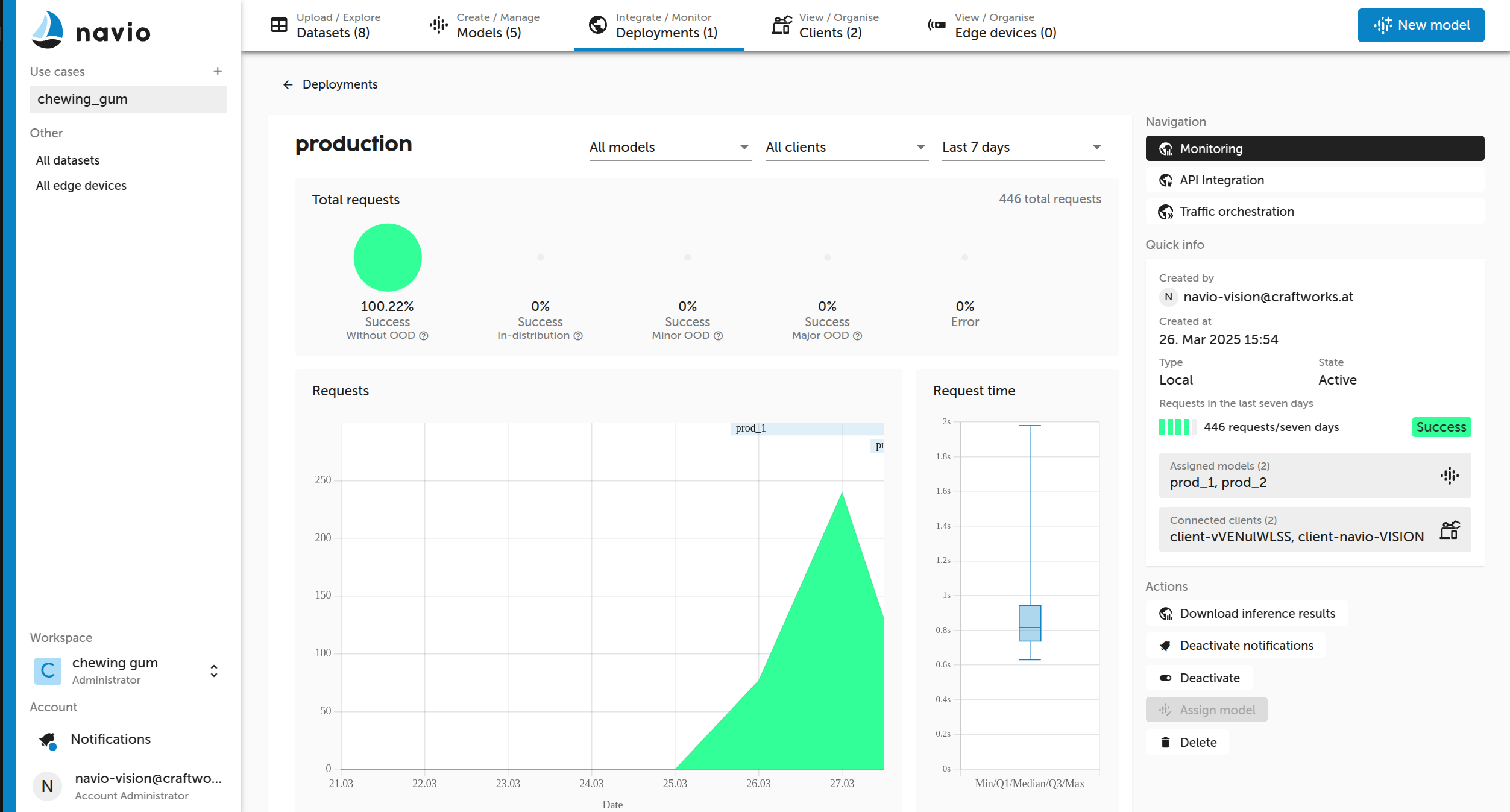

A key feature of navio is its advanced traffic orchestration for production deployments. The following screenshot shows how navio handles multiple models in a production environment, using model shadowing to test and evaluate models in real-time without affecting production responses.

Key features of navio for manufacturing

Key features of navio for manufacturingnavio automates data ingestion from various sources, such as sensors, production systems, and ERP systems. The platform allows manufacturers to create customized data pipelines that facilitate data extraction, preprocessing, and transformation. This ensures that the data used to train machine learning models is consistent and of high quality. This consistency is crucial for achieving accurate results in manufacturing.

Managing and versioning machine learning models can be challenging. This challenge grows when different models run across multiple production lines or plants. navio simplifies this by allowing manufacturers to track model versions, compare performance metrics, and manage updates. This ensures that the most accurate and efficient models are always in use.

Here's an overview of how navio provides a clear and structured view of all models involved in a specific use case, making it easy to track and manage versions.

One of the most powerful features of navio is its highly customizable real-time monitoring. The platform lets manufacturing teams monitor model performance in real time, ensuring AI systems stay aligned with changing conditions. Built-in feedback loops retrain and refine models with fresh data, improving accuracy and performance.

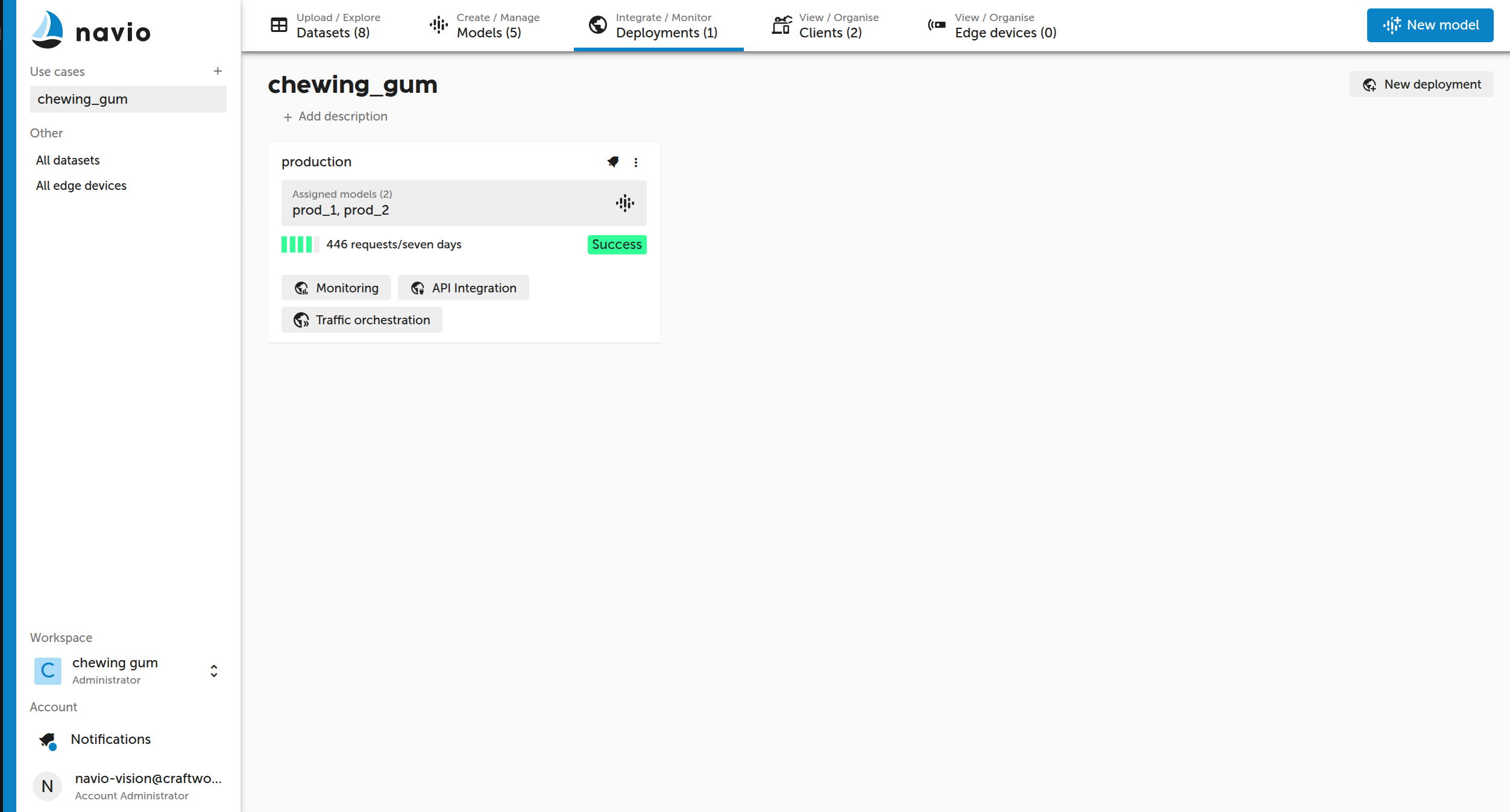

The deployment overview in navio gives a comprehensive snapshot of all active deployments, including real-time performance metrics and status.

4. Collaboration and ability to grow

4. Collaboration and ability to grownavio's MLOps framework includes strong collaboration features that help data scientists, engineers, and operators work together efficiently. Additionally, the platform scales effortlessly to accommodate growing data volumes and expanding production operations.

navio’s deployment monitoring feature also supports collaboration and scalability by providing teams with real-time insights into model performance across different production lines and environments.

navio is central to an effective MLOps strategy, seamlessly integrating with navio VISION. This AI-powered solution specializes in visual anomaly detection, including scrap detection, assembly verification, and packaging inspection. The following success stories highlight how navio VISION dramatically improves manufacturing processes in real-world applications.

navio is central to an effective MLOps strategy, seamlessly integrating with navio VISION. This AI-powered solution specializes in visual anomaly detection, including scrap detection, assembly verification, and packaging inspection. The following success stories highlight how navio VISION dramatically improves manufacturing processes in real-world applications.

A leading manufacturer of industrial bearings faced a significant challenge with inefficient scrap detection, resulting in high rejection rates and unnecessary waste. Their image-based system misclassified many high-quality bearings, leading to unnecessary rejections. By adopting navio VISION, they are able to accurately classify bearings as first or second grade and identify defects.

navio VISION trains machine learning models using high-resolution images to distinguish between OK and NOK parts. As a result, the scrap rate dropped by 50%, classification accuracy reached 94%, and defect identification precision hit 82%. The integration of navio VISION significantly enhances the quality control process, reducing waste and improving production efficiency.

A major industrial manufacturer struggled with packaging defects, such as incorrect labels and missing components, leading to costly recalls and customer unhappiness. The manual inspection process was slow and prone to human error. To address this, the manufacturer deploys navio VISION for real-time packaging inspection. The system uses high-resolution cameras to analyze every package on the production line.

Integrated with the company’s ERP system, navio VISION flags defective packages for removal or correction. The manufacturer reduced recalls by 55%, sped up package inspection by 72%, and improved labeling accuracy and compliance. This solution streamlines quality control, minimizes the risk of costly recalls, ensures regulatory compliance, and increases overall throughput.

A leading solar panel manufacturer had difficulties detecting small defects, like misalignments and cracks, during assembly. These defects could affect the panel's performance and durability. The production line uses navio VISION to capture clear images of the panels during assembly.

The AI models successfully identify micro-defects, including misaligned cells, cracks, and soldering issues. The manufacturer cut inspection time and labor costs by 40% and achieved 99% compliance with quality standards. navio VISION detects defects early, which helps reduce labor costs. This ensures that only high-quality panels are sent to customers.

As industries explore the potential of AI and machine learning, MLOps platforms like navio are becoming more essential. Designed for expansion, navio helps manufacturers constantly optimize processes as AI technologies evolve. According to a recent PwC survey, 70% of manufacturers plan to adopt AI within the next five years. Most of them aim to use AI for predictive maintenance, process optimization, and quality control.

navio is more than just a tool for managing machine learning models. navio helps companies optimize production, reduce costs, and improve quality. It provides the infrastructure needed to scale AI adoption.

The rise of MLOps is transforming the manufacturing industry, and navio stands at the forefront of this transformation. navio provides manufacturers with powerful tools to manage and deploy machine learning models. These features help optimize operations, reduce waste, and maintain high-quality standards. By integrating navio VISION for visual anomaly detection, manufacturers can leverage AI to improve every aspect of their production processes.

As the industry evolves, navio will play a key role in shaping the future of manufacturing. Start with navio to see how our solutions can improve your operations and give you better control over AI.

:quality(80))